Mazak Optonics Blog

Where metal fabricators acquire industry and laser-cutting insights

Upgrade Your Laser Cutting with Automation

The flexibility of Mazak’s automation solutions, like the SMART CELL robotic sorting system, offers first-time buyers and experienced manufacturers simplicity and convenience to automate production. Compatible with Mazak’s flat sheet laser-cutting machines, SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production. Mazak’s automation systems are modular and available in multiple formats to accommodate various production and shop floor constraints.

The flexibility of Mazak’s automation solutions, like the SMART CELL robotic sorting system, offers first-time buyers and experienced manufacturers simplicity and convenience to automate production. Compatible with Mazak’s flat sheet laser-cutting machines, SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production. Mazak’s automation systems are modular and available in multiple formats to accommodate various production and shop floor constraints.

Expanded Parts Facility Streamlines Customer Support

Mazak’s commitment to customer service prompted the investment in an expanded parts facility and the latest automation technologies to maintain a 97% same-day shipping rate on customers’ orders for machine parts. As a leader in manufacturing advanced laser-cutting solutions, Mazak Optonics Corporation prioritizes customer satisfaction. The recent expansion of the parts department aligns with Mazak’s commitment to better serve customers—by increasing capacity for parts and streamlining operations.

Mazak’s commitment to customer service prompted the investment in an expanded parts facility and the latest automation technologies to maintain a 97% same-day shipping rate on customers’ orders for machine parts. As a leader in manufacturing advanced laser-cutting solutions, Mazak Optonics Corporation prioritizes customer satisfaction. The recent expansion of the parts department aligns with Mazak’s commitment to better serve customers—by increasing capacity for parts and streamlining operations.

The Advantages of High-Power Beam Shaping Technology in Laser Cutting

Mazak's proprietary beam shaping technology delivers power through a fiber optic cable but in a multi-core format. With this new technology, operators can decide how much power is in the center versus the outer edges of the beam. The OPTIPLEX 3015 NEO combines this innovative beam control technology with a high 15kW power level for optimal laser-cutting performance.

Mazak's proprietary beam shaping technology delivers power through a fiber optic cable but in a multi-core format. With this new technology, operators can decide how much power is in the center versus the outer edges of the beam. The OPTIPLEX 3015 NEO combines this innovative beam control technology with a high 15kW power level for optimal laser-cutting performance.

What is Beam Shaping Technology in Laser-Cutting?

Laser-cutting technology, like most modern technology, is constantly advancing. From CO2 lasers to fiber lasers, to advanced cutting heads with beam diameter control, and now generators that perform beam shaping. The next development in laser-cutting is here. V-BPP is much different than a standard fiber laser. V-BPP provides a variety of beam shapes, sizes and power distributions that can be used for different cutting techniques and applications.

Laser-cutting technology, like most modern technology, is constantly advancing. From CO2 lasers to fiber lasers, to advanced cutting heads with beam diameter control, and now generators that perform beam shaping. The next development in laser-cutting is here. V-BPP is much different than a standard fiber laser. V-BPP provides a variety of beam shapes, sizes and power distributions that can be used for different cutting techniques and applications.

What are the Mazak Intelligent Functions?

Mazak Optonics utilizes intelligent technology to engineer laser-cutting machines that deliver innovation, performance, automation and value. These automated innovations are called the Mazak Intelligent Functions. When the Intelligent Functions are paired with the Mazak Multi-Control Torch, they work together to provide unrivaled operator support for exceptional ease of operation, offer enhanced quality of processed components as well as reduced cutting time. There are three categories of Mazak’s Intelligent Functions which include: Intelligent Setup Functions (ISF), Intelligent Monitoring Functions (IMF) and Intelligent Cutting Functions (ICF).

Mazak Optonics utilizes intelligent technology to engineer laser-cutting machines that deliver innovation, performance, automation and value. These automated innovations are called the Mazak Intelligent Functions. When the Intelligent Functions are paired with the Mazak Multi-Control Torch, they work together to provide unrivaled operator support for exceptional ease of operation, offer enhanced quality of processed components as well as reduced cutting time. There are three categories of Mazak’s Intelligent Functions which include: Intelligent Setup Functions (ISF), Intelligent Monitoring Functions (IMF) and Intelligent Cutting Functions (ICF).

Post-Sale Support Considerations

![]() Fabricators should consider a variety of factors when adding a new laser-cutting machine to their operations. However, post-sale support is a vital element of laser-cutting operations and should be a focal point when weighing options. It is important to understand what type of service and support will fabricators receive after the laser has been installed. Discover which post-sale support factors to consider when implementing a new laser machine.

Fabricators should consider a variety of factors when adding a new laser-cutting machine to their operations. However, post-sale support is a vital element of laser-cutting operations and should be a focal point when weighing options. It is important to understand what type of service and support will fabricators receive after the laser has been installed. Discover which post-sale support factors to consider when implementing a new laser machine.

Part Sorting and Identification Strategies

![]() While keeping the laser constantly cutting is essential, customers do not pay for machine runtime; they pay for parts. And not the parts that go missing, rework on lost parts, or re-cutting pieces that should have been identified properly in the first place. Now that the laser processes more parts to more downstream machines, strategic part identification and sorting have become even more important. Discover strategies available for part sorting and identification strategies.

While keeping the laser constantly cutting is essential, customers do not pay for machine runtime; they pay for parts. And not the parts that go missing, rework on lost parts, or re-cutting pieces that should have been identified properly in the first place. Now that the laser processes more parts to more downstream machines, strategic part identification and sorting have become even more important. Discover strategies available for part sorting and identification strategies.

The Assist Gas That Saves

Assist gases are the most expensive part of laser-cutting operations. Many fabricators use bulk nitrogen, but considering the cost, they’re often looking to reduce this expense. Typically, a nitrogen generation system comes to mind, however, high-performance dry air systems are also a viable option, if the application allows for it. The outcomes from utilizing high-performance air as an assist gas can dramatically reduce monthly operating costs, increase throughput and reduce laser idle time.

Assist gases are the most expensive part of laser-cutting operations. Many fabricators use bulk nitrogen, but considering the cost, they’re often looking to reduce this expense. Typically, a nitrogen generation system comes to mind, however, high-performance dry air systems are also a viable option, if the application allows for it. The outcomes from utilizing high-performance air as an assist gas can dramatically reduce monthly operating costs, increase throughput and reduce laser idle time.

Ten Tips for Fabricators to Beat the Heat

![]() As temperature rise in the summer, so does concern for workers’ safety and health in manufacturing facilities. Fortunately, there are many precautions workers and managers can take to ensure the work environment and employees are safe during the steamy season. Discover five tips for employees and five tips for managers to beat the summer heat.

As temperature rise in the summer, so does concern for workers’ safety and health in manufacturing facilities. Fortunately, there are many precautions workers and managers can take to ensure the work environment and employees are safe during the steamy season. Discover five tips for employees and five tips for managers to beat the summer heat.

What to do With Your Laser Cut Parts

Laser-cutting automation has been around for over 40 years. Mazak was the first laser manufacturer to implement factory automation in 1984. In the past, many automation systems were cookie cutter and if it did not fit properly in your facility, it was on you to rearrange the shop to make it fit. Today it is a different story. There are many different types of automation layouts that fit into a variety of different shop floors. The latest technology allows for the finished product to be presented in an appropriate manner by allowing you to decide where you want the finished product to go and then we can create the proper automation flow for your fabrication shop.

Laser-cutting automation has been around for over 40 years. Mazak was the first laser manufacturer to implement factory automation in 1984. In the past, many automation systems were cookie cutter and if it did not fit properly in your facility, it was on you to rearrange the shop to make it fit. Today it is a different story. There are many different types of automation layouts that fit into a variety of different shop floors. The latest technology allows for the finished product to be presented in an appropriate manner by allowing you to decide where you want the finished product to go and then we can create the proper automation flow for your fabrication shop.

Fabricators Join the Fight Against COVID-19 Pandemic

![]() Mazak Optonics’ customers have joined the fight to help flatten the curve of COVID-19. These fabricators were deemed as essential businesses during stay-at-home executive orders and have been able to continue operations. In addition, these companies have initiated new projects, such as making essential items, to help during the pandemic. Learn more about these fabricators who are producing items to assist with the fight against COVID-19.

Mazak Optonics’ customers have joined the fight to help flatten the curve of COVID-19. These fabricators were deemed as essential businesses during stay-at-home executive orders and have been able to continue operations. In addition, these companies have initiated new projects, such as making essential items, to help during the pandemic. Learn more about these fabricators who are producing items to assist with the fight against COVID-19.

COVID-19 Relief Resources for Fabricators

Fabricators and manufacturers are part of the Coronavirus frontline. We are being called on to be part of the solution and to help during this time. To help with suppling PPE and medical equipment to arm our healthcare workers but also, to help make daily life continue. This is essential. Here are the current COVID-19 relief offerings available to fabricators, manufacturers and small businesses.

Fabricators and manufacturers are part of the Coronavirus frontline. We are being called on to be part of the solution and to help during this time. To help with suppling PPE and medical equipment to arm our healthcare workers but also, to help make daily life continue. This is essential. Here are the current COVID-19 relief offerings available to fabricators, manufacturers and small businesses.

Reducing Sheet Metal Injuries in Metal Fabrication

It is no surprise that working in the metal fabrication industry can be dangerous at times. With sharp edges and varying weight, sheet metal increases the potential risk for an injury to occur. By wearing the required personal protective equipment, following proper material handling procedures and keeping an orderly shop, you can minimize potential risks to your business.

It is no surprise that working in the metal fabrication industry can be dangerous at times. With sharp edges and varying weight, sheet metal increases the potential risk for an injury to occur. By wearing the required personal protective equipment, following proper material handling procedures and keeping an orderly shop, you can minimize potential risks to your business.

The Three Biggest Upgrades to Mazak’s SMART Glasses

![]() Wearable technology is being integrated in many ways in the industrial world, one of those ways is through Mazak’s SMART Glasses. Mazak has upgraded their SMART Glasses solution to better facilitate virtual support. The upgraded Mazak SMART Glasses overall have a new look and are now more stable, robust and user-friendly. Learn more about the top three improvements and how they benefit users.

Wearable technology is being integrated in many ways in the industrial world, one of those ways is through Mazak’s SMART Glasses. Mazak has upgraded their SMART Glasses solution to better facilitate virtual support. The upgraded Mazak SMART Glasses overall have a new look and are now more stable, robust and user-friendly. Learn more about the top three improvements and how they benefit users.

What to Know When Financing Capital Equipment

![]() You found the laser machine to grow your business but how does financing capital equipment work? Purchasing capital equipment is one of the most common reasons that small businesses look for outside financing. Having the ability to upgrade or add new machinery to your operations allows companies to grow without having to pay for it all up front. There are three common options that fabricators and manufacturers have available to secure financing for their capital equipment.

You found the laser machine to grow your business but how does financing capital equipment work? Purchasing capital equipment is one of the most common reasons that small businesses look for outside financing. Having the ability to upgrade or add new machinery to your operations allows companies to grow without having to pay for it all up front. There are three common options that fabricators and manufacturers have available to secure financing for their capital equipment.

Apprenticeship Creates Careers in Fabrication

Maintaining a full-capacity of skilled workers has become a challenge among companies in the manufacturing and fabrication industries. The high demand for more skilled workers is what led Mazak Optonics to create an apprenticeship program at Mazak. After successfully completing the apprenticeship program, Shaikh, Luna, Avitia, Barnett, and Brown have earned a new career with Mazak.

Maintaining a full-capacity of skilled workers has become a challenge among companies in the manufacturing and fabrication industries. The high demand for more skilled workers is what led Mazak Optonics to create an apprenticeship program at Mazak. After successfully completing the apprenticeship program, Shaikh, Luna, Avitia, Barnett, and Brown have earned a new career with Mazak.

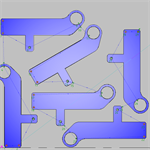

Quick Start Guide to Tube Lasers

![]() Tubes and pipes have found a growth in applications with continued advancements in tube technology. Tube lasers continued to get faster while also processing an increased range of materials types and shapes. While fabrication often focuses on flat sheeting material processing, tube and pipes fabrication is also a major player. Here is a quick start guide for what to think about with tube and pipe laser-cutting.

Tubes and pipes have found a growth in applications with continued advancements in tube technology. Tube lasers continued to get faster while also processing an increased range of materials types and shapes. While fabrication often focuses on flat sheeting material processing, tube and pipes fabrication is also a major player. Here is a quick start guide for what to think about with tube and pipe laser-cutting.

Fab(rication) Females

When people think of the manufacturing and fabrication industry, one of the first things that comes to mind is “male-dominated”. While this is accurate, it is important to encourage women to consider careers in manufacturing and fabrication. But how can we get more women in fabrication and manufacturing? Two fabrication females at Mazak Optonics Katie Menrath and Michelle Redish share their stories about their careers in the fabrication industry.

When people think of the manufacturing and fabrication industry, one of the first things that comes to mind is “male-dominated”. While this is accurate, it is important to encourage women to consider careers in manufacturing and fabrication. But how can we get more women in fabrication and manufacturing? Two fabrication females at Mazak Optonics Katie Menrath and Michelle Redish share their stories about their careers in the fabrication industry.

Importance of Preventative Fiber Laser Maintenance

Cleaning is a dreaded chore by all. However, in order to keep laser-cutting machines in optimal condition, cleaning and maintenance are crucial. This guide will reference benefits of preventative maintenance, where to clean on your fiber laser, resources to utilize for maintenance, and how Mazak Service is here to assist you.

Cleaning is a dreaded chore by all. However, in order to keep laser-cutting machines in optimal condition, cleaning and maintenance are crucial. This guide will reference benefits of preventative maintenance, where to clean on your fiber laser, resources to utilize for maintenance, and how Mazak Service is here to assist you.

Why High Power?

When you flip through any of the fabrication magazines, you will see advertisements and press releases all mentioning high-power lasers, which includes 6kW, 8kW, and 10kW. Why is it that the industry wants these higher power levels for laser-cutting? There are a variety of productivity and quality benefits that are realized when using higher power levels with laser-cutting. Discover why you need a high-power fiber laser-cutting machine in your fabrication operations.

When you flip through any of the fabrication magazines, you will see advertisements and press releases all mentioning high-power lasers, which includes 6kW, 8kW, and 10kW. Why is it that the industry wants these higher power levels for laser-cutting? There are a variety of productivity and quality benefits that are realized when using higher power levels with laser-cutting. Discover why you need a high-power fiber laser-cutting machine in your fabrication operations.

Marketing 101 for Job Shops

Marketing is involved through all stages of business and is a critical aspect to any company, even fabrication job shops. With new tactics and strategies coming out every year, it is hard to keep up with what is most impactful for fabricators. These three marketing basics can help your fabrication shop gain a solid marketing base, so you can focus on the engineering ahead.

Marketing is involved through all stages of business and is a critical aspect to any company, even fabrication job shops. With new tactics and strategies coming out every year, it is hard to keep up with what is most impactful for fabricators. These three marketing basics can help your fabrication shop gain a solid marketing base, so you can focus on the engineering ahead.

Five Laser-Cutting Trends of 2019

By understanding the fabrication industry’s pain points, Mazak strives to fit your needs and improve your operations. Here are the top 5 laser-cutting trends that we are seeing in the fabrication industry that will drive the future of laser processing.

By understanding the fabrication industry’s pain points, Mazak strives to fit your needs and improve your operations. Here are the top 5 laser-cutting trends that we are seeing in the fabrication industry that will drive the future of laser processing.

Automation Implementation Helps Fill Skills Gap Created by Aging Workforce

With baby boomers aging in droves, the challenge now is the loss of skills from one generation to the next. Unemployment levels are at an all-time low across the country which means it is increasingly more difficult to hire, replace and train new employees with enough time to transfer vital information to the new hire. Skills are gained over years; it isn’t easy for novice employees to replicate without side-by-side training. But what is the answer to the aging workforce and increasing skills gap?

With baby boomers aging in droves, the challenge now is the loss of skills from one generation to the next. Unemployment levels are at an all-time low across the country which means it is increasingly more difficult to hire, replace and train new employees with enough time to transfer vital information to the new hire. Skills are gained over years; it isn’t easy for novice employees to replicate without side-by-side training. But what is the answer to the aging workforce and increasing skills gap?

The 3D FABRI GEAR Advantage

![]() The 3D FABRI GEAR line was introduced in 1999 and since then Mazak has continued to advance their 3D laser-cutting technology. From a true 3D cutting head to the Mazak four-chuck system, the FABRI GEAR incredibly unique. The done-in-one process saves a number of hours and offers a better chance of making consistently accurate parts.

The 3D FABRI GEAR line was introduced in 1999 and since then Mazak has continued to advance their 3D laser-cutting technology. From a true 3D cutting head to the Mazak four-chuck system, the FABRI GEAR incredibly unique. The done-in-one process saves a number of hours and offers a better chance of making consistently accurate parts.

One Year Later: 2019 Steel and Tariffs Outlook

The past, present and future of tariffs, steel, service centers and fabricators. Since entering The Oval Office, President Trump has implemented many new policies for the United States. One of these impactful decisions was announced through the President’s Twitter in March 2018. Trump’s decision was to set tariffs of 25 percent on imported steel and 10 percent on aluminum which was put into effect in June 2018. What has happened since implementing these tariffs and where are we at now? These questions are answered differently depending where you stand in the metals industry.

The past, present and future of tariffs, steel, service centers and fabricators. Since entering The Oval Office, President Trump has implemented many new policies for the United States. One of these impactful decisions was announced through the President’s Twitter in March 2018. Trump’s decision was to set tariffs of 25 percent on imported steel and 10 percent on aluminum which was put into effect in June 2018. What has happened since implementing these tariffs and where are we at now? These questions are answered differently depending where you stand in the metals industry.

Five Tips for 2D Software Programming

Five Tips for Programming 2D Software for Mazak laser-cutting machines. Maximize your laser-cutting production and minimize loss by utilizing these five Mazak Smart System software programming tools and techniques. Check out these five major techniques and tools that you can use with Mazak Smart System to make your laser-cutting processes most efficient.

Five Tips for Programming 2D Software for Mazak laser-cutting machines. Maximize your laser-cutting production and minimize loss by utilizing these five Mazak Smart System software programming tools and techniques. Check out these five major techniques and tools that you can use with Mazak Smart System to make your laser-cutting processes most efficient.

Cheers to 100 Years!

A fabricator’s guide to laser-cutting assist gases: Whether you are new to laser-cutting or need a refresher course, here is what you need to know regarding assist gases. This laser-cutting assist gas guide is here to refine your understanding regarding the difference gases and why they are used.

A fabricator’s guide to laser-cutting assist gases: Whether you are new to laser-cutting or need a refresher course, here is what you need to know regarding assist gases. This laser-cutting assist gas guide is here to refine your understanding regarding the difference gases and why they are used.

Cutting Assistance

A fabricator’s guide to laser-cutting assist gases: Whether you are new to laser-cutting or need a refresher course, here is what you need to know regarding assist gases. This laser-cutting assist gas guide is here to refine your understanding regarding the difference gases and why they are used.

A fabricator’s guide to laser-cutting assist gases: Whether you are new to laser-cutting or need a refresher course, here is what you need to know regarding assist gases. This laser-cutting assist gas guide is here to refine your understanding regarding the difference gases and why they are used.

Are you utilizing the R&D Tax Credit?

![]() Are you looking for ways to save money, expand your business while improving your company’s bottom line? The R&D Tax Credit is an opportunity that allows you to take advantage of activities that you are probably already performing. Yet shockingly, it is estimated that only 5 percent of eligible companies claim the R&D Tax Credit. Largely as a result of the ongoing improvements made to their products and processes, manufacturers make up the largest group of R&D Tax Credit claimants. Each year, manufacturers receive considerable tax savings as a result of this government-sponsored incentive.

Are you looking for ways to save money, expand your business while improving your company’s bottom line? The R&D Tax Credit is an opportunity that allows you to take advantage of activities that you are probably already performing. Yet shockingly, it is estimated that only 5 percent of eligible companies claim the R&D Tax Credit. Largely as a result of the ongoing improvements made to their products and processes, manufacturers make up the largest group of R&D Tax Credit claimants. Each year, manufacturers receive considerable tax savings as a result of this government-sponsored incentive.

Unconstrained Automation

![]() Automation is not a one-size-fits-all solution due to the many shop floor constraints, but all is not lost, partner with a builder that best customizes individual needs. Mazak offers endless configuration possibilities with their extensive and customizable automation solutions. When searching for automation, make sure that your requirements are being met and the system is able to keep up with the pace of your fiber laser-cutting machines.

Automation is not a one-size-fits-all solution due to the many shop floor constraints, but all is not lost, partner with a builder that best customizes individual needs. Mazak offers endless configuration possibilities with their extensive and customizable automation solutions. When searching for automation, make sure that your requirements are being met and the system is able to keep up with the pace of your fiber laser-cutting machines.

GENCO and Mazak Credit Corp. Partner to Invest in New Mazak Fiber Laser

![]() Genco Manufacturing Inc. has been producing quality fabricated metal products for over 30 years in Garnett, KS. Originally started as a fab shop but since then has decided to diversify by getting into the truck bed market. Previously building custom made to order truck beds, GENCO was specializing in custom products designed to meet customer's specifications at competitive prices. hile at FABTEH, GENCO decided to purchase a Mazak OPTIPLEX NEXUS 3015 Fiber laser-cutting system. The OPTIPLEX NEXUS Fiber laser was the answer to their increase in demand and continued growth. GENCO ended up taking advantage of the special Mazak Credit Corp (MCC) financing promotional rate for their first Mazak laser-cutting machine.

Genco Manufacturing Inc. has been producing quality fabricated metal products for over 30 years in Garnett, KS. Originally started as a fab shop but since then has decided to diversify by getting into the truck bed market. Previously building custom made to order truck beds, GENCO was specializing in custom products designed to meet customer's specifications at competitive prices. hile at FABTEH, GENCO decided to purchase a Mazak OPTIPLEX NEXUS 3015 Fiber laser-cutting system. The OPTIPLEX NEXUS Fiber laser was the answer to their increase in demand and continued growth. GENCO ended up taking advantage of the special Mazak Credit Corp (MCC) financing promotional rate for their first Mazak laser-cutting machine.

Safety First

Mazak laser-cutting machines are incredibly safe machines but it is also necessary to follow proper procedure to reduce risks. Laser is actually an acronym for "light amplification by stimulated emission of radiation". Since there is a radiation stimulated light involved in the Mazak cutting process, there are potential hazards. Laser related hazards include laser beam contact, fire, fumes and electrocution. But the two most serious are beam contact and fire.

Mazak laser-cutting machines are incredibly safe machines but it is also necessary to follow proper procedure to reduce risks. Laser is actually an acronym for "light amplification by stimulated emission of radiation". Since there is a radiation stimulated light involved in the Mazak cutting process, there are potential hazards. Laser related hazards include laser beam contact, fire, fumes and electrocution. But the two most serious are beam contact and fire.

Mazak's Solution to IIoT Cyber Security

Mazak's iSMART Factory Solution connections machines to a network where the data is displayed and now readable in a visual format. This electronic data is prone to threats such as malware, spyware and ransomware. Keeping this data secure is vital, which is why Mazak has the SmartBox to protect your shop floor.

Mazak's iSMART Factory Solution connections machines to a network where the data is displayed and now readable in a visual format. This electronic data is prone to threats such as malware, spyware and ransomware. Keeping this data secure is vital, which is why Mazak has the SmartBox to protect your shop floor.

Wishlist Achieved

IIoT and customer input help shape the laser machine controls of today and tomorrow with the new PreviewG control. Having an easy-to-use, fast, smart and IoT connected laser cutting control is what customers want. The capabilities of looking further ahead, being ergonomical, tracking cutting and maintenance, and showing in real-time what is happening at the fiber laser machine make the PreviewG control a game changer for laser-cutting technology.

IIoT and customer input help shape the laser machine controls of today and tomorrow with the new PreviewG control. Having an easy-to-use, fast, smart and IoT connected laser cutting control is what customers want. The capabilities of looking further ahead, being ergonomical, tracking cutting and maintenance, and showing in real-time what is happening at the fiber laser machine make the PreviewG control a game changer for laser-cutting technology.

Mazak Optonics sees customer service through a new set of lenses

Mazak Optonics now offers the latest in wearable smart technology offering Mazak SMART Glasses. These glasses enable a Mazak Service Technician to remotely view what your laser operator sees by utilizing telepresence technology. Learn more about the Mazak SMART Glasses and their benefits here in the Mazak Optonics blog post.

Mazak Optonics now offers the latest in wearable smart technology offering Mazak SMART Glasses. These glasses enable a Mazak Service Technician to remotely view what your laser operator sees by utilizing telepresence technology. Learn more about the Mazak SMART Glasses and their benefits here in the Mazak Optonics blog post.

Women Impacting the Manufacturing Industry

The skills gap is nothing new to US manufacturing but as it continues to widen over the next decade, 3.4 million jobs will be needed. Women total roughly 47 percent of US jobs, yet the manufacturing workforce is only made up of approximately 29 percent women. Even with women being a small percentage of the manufacturing workforce, they are already improving the industry immensely. Women are an essential part of manufacturing and will continue to be in the future. I have been fortunate enough to chat with some of these women who are paving the way for successful careers in manufacturing.

The skills gap is nothing new to US manufacturing but as it continues to widen over the next decade, 3.4 million jobs will be needed. Women total roughly 47 percent of US jobs, yet the manufacturing workforce is only made up of approximately 29 percent women. Even with women being a small percentage of the manufacturing workforce, they are already improving the industry immensely. Women are an essential part of manufacturing and will continue to be in the future. I have been fortunate enough to chat with some of these women who are paving the way for successful careers in manufacturing.

Are Trump's Tariffs on Steel and Aluminum Good or Bad?

Since his campaign began, President Trump has been pro-manufacturing and anti-foreign steel and aluminum. President Trump said the dumping of foreign metals puts America at a national-security risk. President Trump on March 5th, tweeted, “To protect our country we must protect American Steel!” On March 1st, President Donald Trump has announced to impose a 25 percent tariff on imported steel and a 10 percent tariff on imported aluminum. But what does this mean for fabricators and manufacturers? The potential effects are still in question on whether this is a good or bad deal.

Since his campaign began, President Trump has been pro-manufacturing and anti-foreign steel and aluminum. President Trump said the dumping of foreign metals puts America at a national-security risk. President Trump on March 5th, tweeted, “To protect our country we must protect American Steel!” On March 1st, President Donald Trump has announced to impose a 25 percent tariff on imported steel and a 10 percent tariff on imported aluminum. But what does this mean for fabricators and manufacturers? The potential effects are still in question on whether this is a good or bad deal.

Employee Retention: A Proactive Approach to the Skills Gap

![]() As of January 2018, the unemployment rate has steadily been at 4.1 percent in the United States according to a press release by the U.S. Bureau of Labor Statistics. The release also added that payroll employment has continued to rise for manufacturing, adding 186,000 jobs in the past 12 months. The quits rate is back to pre-recession peak of 2.2 percent. High employee turnover can reduce productivity, increase costs for businesses, and leave organizational goals unmet. With limited skilled workers, more jobs, and higher quit rates it makes it that much more important to keep the employees you have happy. With the current war on top talent, how do fabricators keep their top employees?

As of January 2018, the unemployment rate has steadily been at 4.1 percent in the United States according to a press release by the U.S. Bureau of Labor Statistics. The release also added that payroll employment has continued to rise for manufacturing, adding 186,000 jobs in the past 12 months. The quits rate is back to pre-recession peak of 2.2 percent. High employee turnover can reduce productivity, increase costs for businesses, and leave organizational goals unmet. With limited skilled workers, more jobs, and higher quit rates it makes it that much more important to keep the employees you have happy. With the current war on top talent, how do fabricators keep their top employees?

The Impact of the Trump Tax Reform

The last time the United States had a comprehensive tax revamp was in 1986. After 32 years, on December 22 the latest tax reform bill was made into law. There have been a many different views on the new law. But what it is important is how the bill affects your business. Here is a quick rundown on the benefits of the new law, opportunities and uncertainties.

The last time the United States had a comprehensive tax revamp was in 1986. After 32 years, on December 22 the latest tax reform bill was made into law. There have been a many different views on the new law. But what it is important is how the bill affects your business. Here is a quick rundown on the benefits of the new law, opportunities and uncertainties.

Understanding the Mazak iSMART Factory Solution

The Mazak iSMART Factory Solution is based on over 36 years of Mazak’s industry leading experience. Learn how it works through Smooth Monitor AX, SmartBox, and MT Connect.

The Mazak iSMART Factory Solution is based on over 36 years of Mazak’s industry leading experience. Learn how it works through Smooth Monitor AX, SmartBox, and MT Connect.

American Oil and Natural Gas Opportunity

![]() Energy is a key factor for both emerging economies and developed countries. Energy is central to social and economic well-being. New strategies and technologies can allow energy to be accessible to all by 2030, allowing energy to move from poverty towards prosperity. The two major energies that could impact fabricators in the United States are oil and natural gas.

Energy is a key factor for both emerging economies and developed countries. Energy is central to social and economic well-being. New strategies and technologies can allow energy to be accessible to all by 2030, allowing energy to move from poverty towards prosperity. The two major energies that could impact fabricators in the United States are oil and natural gas.

Is Automation the Right Move?

This blog post highlights the four key steps in considering automation: 1. Do you really need automation? 2. What type of automation do you need? 3. What should your initial configuration look like? 4. What are the challenges you may face implementing an automation system?

This blog post highlights the four key steps in considering automation: 1. Do you really need automation? 2. What type of automation do you need? 3. What should your initial configuration look like? 4. What are the challenges you may face implementing an automation system?

Make Fabrication Great Again

![]() With recent changes in Washington, there have been 22 executive orders and an array of Presidential Memorandums and Presidential proclamations issues. With with these changes fabricators are feeling good, here is why.

With recent changes in Washington, there have been 22 executive orders and an array of Presidential Memorandums and Presidential proclamations issues. With with these changes fabricators are feeling good, here is why.

What is Direct Diode Laser Technology?

![]() Mazak Optonics Corp. introduced a first of its kind laser-cutting machine which utilized a direct diode laser (DDL), the OPTIPLEX 3015 DDL. This machine changed the game for high power laser cutting. Direct diode laser technology has shaken the industrial laser-cutting industry, but not everyone understands what it is, how it works or why it has gained such traction.

Mazak Optonics Corp. introduced a first of its kind laser-cutting machine which utilized a direct diode laser (DDL), the OPTIPLEX 3015 DDL. This machine changed the game for high power laser cutting. Direct diode laser technology has shaken the industrial laser-cutting industry, but not everyone understands what it is, how it works or why it has gained such traction.