Increase the longevity of your fiber laser-cutting machine by following preventative maintenance procedures

By Megan Tsevelekos, Marketing Specialist at Mazak Optonics Corp.

Cleaning is a dreaded chore by all. However, in order to keep laser-cutting machines in optimal condition, cleaning and maintenance are crucial. For cars, the better you maintain its components, the longer it will run due to maintained quality. This analogy also works for providing preventative maintenance for lasers. Fabricators invest hefty amounts in laser-cutting equipment, so it makes sense to want to maintain your current assets. While fiber lasers require less maintenance than a CO2 laser, there are still preventative maintenance actions that can be taken. By performing preventative maintenance on fiber laser machines, fabricators will see several benefits including cost savings and increased longevity of machine lifespan. This guide will reference benefits of preventative maintenance, where to clean on a fiber laser, resources to utilize for maintenance, and how Mazak Service is here to assist.

Benefits of performing preventative maintenance

There are many benefits to performing preventative maintenance on laser-cutting machines. Keeping up with maintenance increases the longevity of the machine’s lifespan. Lasers are a large investment and fabricators should strive to think long term rather than short term with their equipment. Mike Chase, Field Service Engineer at Mazak Optonics, states, “Yes, cleaning your machine takes some time away from production, but in the long run your preventative maintenance efforts will pay off. Not only does preventative maintenance increase your laser machine’s lifespan, but the cleanliness of the machine makes operations run more smoothly which also leads to fewer unscheduled downtime.”

Of all the benefits preventative maintenance offer, the most important benefit to fabricators is that it saves money. Cost savings that fabricators can see include reduced service bills and minimize inactivity of your laser machine.

A fabricator’s dream come true would be a solution to reducing a service bill. When service is needed for a laser-cutting machine, additional time could be required for a service engineer’s visit if the laser is not cleaned prior to arrival. Having your laser machine already cleaned can reduce the cost of service and is a crucial initial step to service procedures.

While a reduced service visit bill is great, fabricators really do not want an inactive machine limiting production. Performing preventative maintenance helps minimize the possibility of machine inactivity. The quicker your laser-cutting machine is active after maintenance, the faster fabricators can return to production, making parts and making money.

Where to clean on fiber lasers

Before grabbing any cleaning supplies, laser operators need to understand what to look for when preparing to clean a fiber laser machine. Here are recommended areas on fiber lasers to inspect for cleaning and preventative maintenance.

Torch

The torch is the epicenter of performing laser-cutting operations. Parts of the torch that laser operators can clean include the torch body, attached lines and cables, the nozzle and the protective window. Another area to inspect for cleaning is the cover over the Z-axis.

Supplies to use for cleaning the torch include using Texwipes or a clean lint-free rag with isopropyl alcohol. Wipe down these areas so the torch is free from any debris. By keeping the torch clean, you can achieve consistent quality in your laser operations.

Drive system

Another component to maintain is the laser machine’s drive system. The drive system runs the X-axis, Y-axis, and Z-axis of the laser machine, which navigates the torch for cutting operations. Drive components to inspect are belts and bellows.

To clean the belts and bellows, you can use a soft brush, vacuum, or rag to remove any byproducts from the laser-cutting process. Cleaning these drive components prevents premature failure and component wear.

Slats

Slats also need to be inspected prior to cutting operations. It is important to measure the height of your slats periodically. Slats that are not at the proper height, due to wear, prevent your laser from initiating cutting procedures. The torch will attempt to travel below your laser’s software limits, which it cannot, therefore causing an alarm.

In order to maintain proper height for your slats and to reduce slag buildup, use tools specifically made for removing slag from slats or manually remove the buildup.

Be sure these outlined areas are free of debris, grease, and any dross that may affect cutting operations. When cleaning your Mazak laser, it is important to follow safety precautions as well. Before performing any maintenance, make sure your laser-cutting machine is turned off. You can also press the emergency stop to ensure it will not turn on during cleaning. Cleaning with the proper materials hinders the opportunity for fire occurrences during operations. Now that you know the basics of fiber laser cleaning, it is important to stay up-to-date when planning and performing preventative maintenance procedures.

Resources for planning and performing maintenance

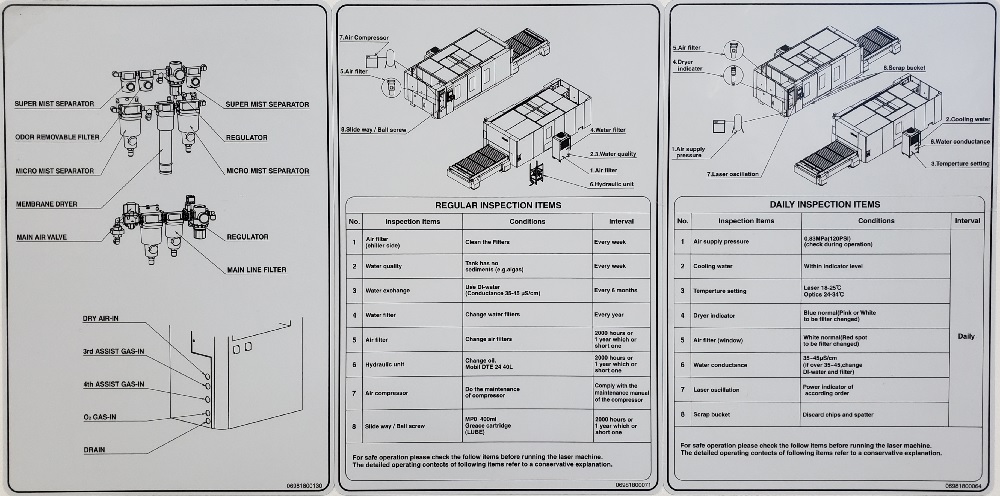

Laser operators can refer to several resources for maintenance tips and inspection checklists. The first resource to refer to is the placard on the side of the Mazak laser machine. This placard includes daily inspections and maintenance procedures that laser operators should follow. Pictured below is an example of what the placard looks like on a Mazak laser. The placard is located on the side of the laser-cutting machine in the vicinity of the CNC. Each placard is specific to the machine it is located on, so it is recommended to follow the requirements outlined for the specific laser machine you are operating.

Another resource is the machine manual for Mazak fiber lasers. The machine manual gives detailed descriptions on maintenance guidelines. Included in the manual are tables that inform laser operators how often maintenance tasks need to be performed and by whom. Some maintenance tasks can be performed by the laser operator, while other tasks need the expertise of Mazak Service Engineers. Following these preventative maintenance tables in the Mazak laser machine manual will help keep laser performance at optimal conditions.

Mazak’s PreviewG control also provides laser operators data to assist with machine maintenance. The PreviewG has a maintenance screen, which includes reminders for general preventative maintenance items, such as changing the air filter. There is also data on run time for items like the protective window and nozzle. The maintenance for these components varies on how much the machine is running and what materials you are cutting. Viewing this data from the PreviewG control allows you to be aware of component usage.

When referring to these resources, be sure to schedule any preventive maintenance checks with Mazak Service in advance to ensure a timely arrival. According to Chase, “It is better to be proactive when scheduling preventative maintenance checks with Mazak Service instead of waiting for your laser to have unscheduled downtime and requesting an emergency visit.” But, if an emergency visit is needed, Mazak Service will come to the rescue.

Mazak is here to help

Even after taking preventative maintenance steps, laser cutting-machines can still encounter complications. If your laser machine has interrupted operation, Mazak Service is here to help.

If your laser-cutting machine has an alarm, it is recommended to contact Mazak Service. The earlier you contact the Mazak Service team regarding an alarm, the quicker the machine can return to cutting operations. “Instead of trying to troubleshoot alone, call Mazak phone support and work with a Technical Support Engineer to help you troubleshoot. This will give you a stronger chance of achieving the repair without even requiring a service visit,” says Chase.

When contacting Mazak Service, it is recommended to fully explain the details regarding the errors occurring on the machine. The more details Mazak Service has, the sooner they can confirm the solution and get your laser back up and cutting quicker.

Before calling Mazak Service, please include these details for an efficient phone call:

- Laser machine serial number

- Hours ran on the laser machine

- Alarm numbers and verbiage

You can contact Mazak Service by phone at 1-888-MAZAK-US (629-2587) or by email at service@mazaklaser.com. Mazak Service Support Hours are Monday-Friday from 6:30 am to 10:30 pm CST, and Saturday-Sunday from 8:00 am to 8:00 pm CST. When you call on a weekday after 7:30 pm CST or on a weekend, please leave a voicemail and you will be contacted shortly by after hours support.

Keeping fiber lasers well maintained is beneficial for fabricators in the long run. Preventative maintenance will increase the longevity of the machine, provide optimal cutting performance, and save fabricators money. By utilizing the outlined resources, laser operators will know what to inspect for cleaning and when to perform maintenance. Always remember that Mazak’s team is here for you when your laser operations run into any complications.