Flexibility of Mazak’s automation solutions, like the SMART CELL robotic sorting system, offers first-time buyers and experienced manufacturers simplicity and convenience to automate production

By Jacob Fogarty, Automation Specialist, and Atika Rafiq, Sr. Marketing Specialist, at Mazak Optonics Corp.

Manufacturers across the United States are dealing with labor shortages, and there does not appear to be an end in sight. The National Association of Manufacturing (NAM) predicts 2.1 million U.S. manufacturing jobs could go unfilled by 2030. With plenty of work and not enough workers, many business owners are looking for ways to keep up with demand while coping with staff shortages.

Benefits of Automation with Laser Cutting

Automation is a practical solution many businesses can implement. Available in various sizes and configurations, Mazak’s automation systems are customizable to the unique needs of each business based on budget and space constraints. Most automation solutions are compatible with existing laser equipment to enhance current production processes. Business owners do not need to invest in new equipment to take advantage of the benefits automation has to offer.

Efficiency is one of the main advantages of implementing automation. Automation systems can keep up with the faster cutting speeds high-power lasers offer by loading and unloading material quickly. Additionally, automation allows operators to work lights out. By programming jobs ahead of time, operators can schedule laser and automation solutions to work overtime and produce more parts without the need for additional manpower.

Utilizing automation to handle more mundane and repetitive tasks prioritizes employee safety due to a decreased chance of human error and injury. Leaders can redirect and train team members to handle more specialized tasks that require specific skillsets.

Tailored to Your Needs

Each manufacturer has a unique production process that requires customized solutions for optimal performance. Laser and automation solutions from Mazak are tailored to the particular needs of each fabricator. Laser machines are available in a range of power levels and platforms; individuals can select the power level and machine size best suited for their cutting specifications.

Automation systems are modular and can be combined to create an optimized solution. Available in multiple formats, Mazak’s automation systems are adaptable to accommodate various production and shop floor constraints. Manufacturers with limited space can utilize compact, linear, or vertical space.

|

|

|

Innovative Solutions

As the first manufacturer to introduce laser-cutting machines into a Flexible Manufacturing System, Mazak continues to innovate laser and automation offerings to better serve customers’ needs. The development of advanced automation solutions to assist in material handling provides users with increased capacity and flexibility.

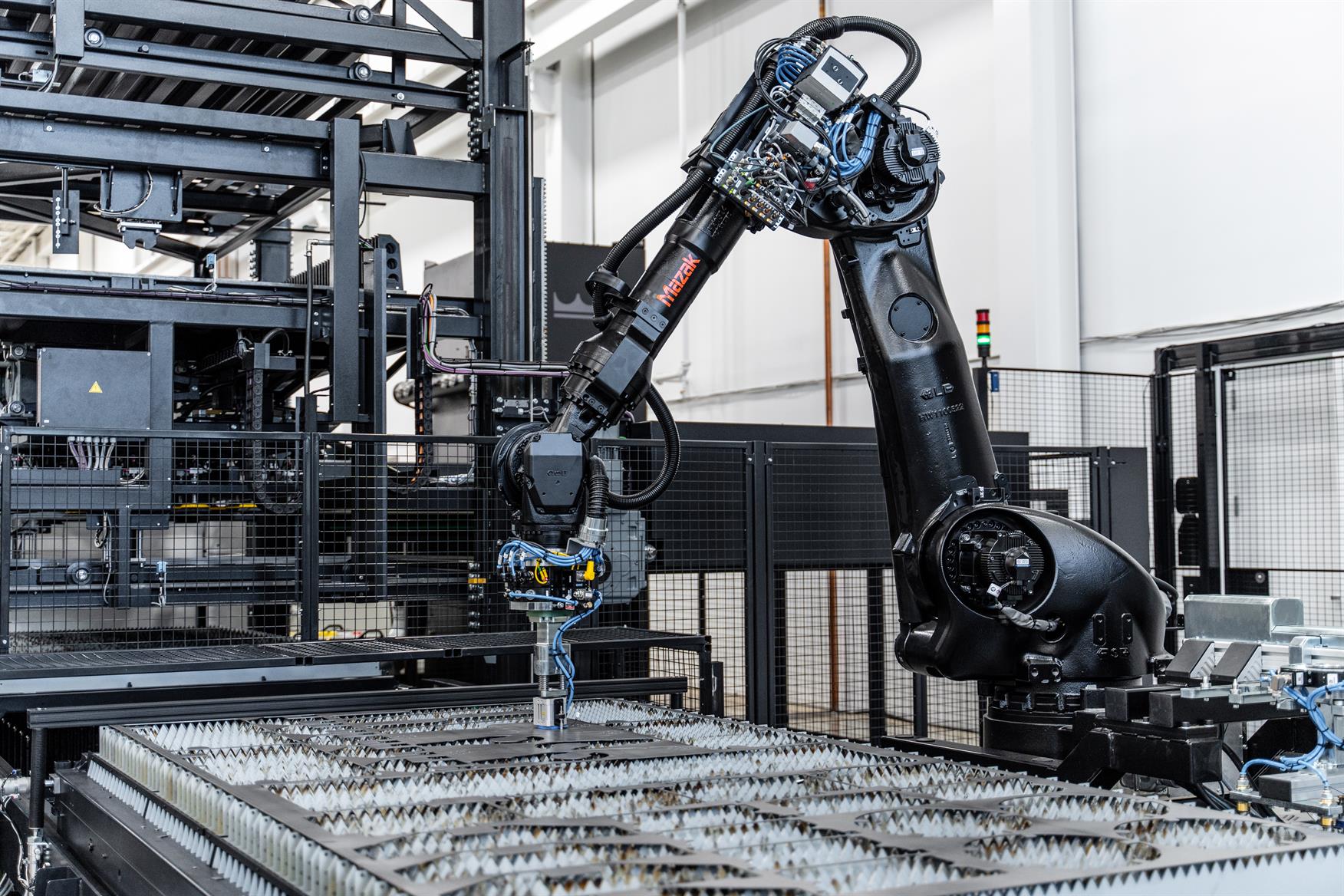

The release of Mazak’s SMART CELL robotic part sorting system showcases the advantages of automated sorting capabilities and provides insight into the future of automation.

SMART CELL Robotic Sorting

Mazak’s SMART CELL is a 6-axis robot that utilizes interchangeable magnetic and suction cup grippers to sort laser-cut parts, load raw material, and remove remnant material. The magnetic heads are used to pick and place mild steel parts while the suction cup grippers are ideal for material that is not magnetic, like stainless and aluminum.

|

|

|

SMART CELL can be customized to accommodate the needs of most shop environments. The sorting system is available in multiple size and payload options to sort a wide range of geometry, with the base design featuring a small 20’ x 20’ footprint.

Ideal for first-time automation users, SMART CELL offers an easy-to-use  interface. SMART CELL utilizes Mazak’s SMART SYSTEM software to identify the location of each part based on cutting data from the laser. A drag-and-drop feature simplifies programming the robot to unload laser-cut parts in specified positions and arrangements. SMART CELL is the perfect solution for production environments running similar or repetitive jobs. The software’s ease of use also makes it a great solution for job shops running multiple parts of different nests.

interface. SMART CELL utilizes Mazak’s SMART SYSTEM software to identify the location of each part based on cutting data from the laser. A drag-and-drop feature simplifies programming the robot to unload laser-cut parts in specified positions and arrangements. SMART CELL is the perfect solution for production environments running similar or repetitive jobs. The software’s ease of use also makes it a great solution for job shops running multiple parts of different nests.

Compatible with Mazak’s flat sheet laser-cutting machines, SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production. Integrating storage tower solutions with SMART CELL allows the automation tower to load/unload material while the robot unloads finished parts for faster run times. The K-Series Tower (KST) solution is one of the many automation options compatible with Mazak’s SMART CELL robot. KST is fully customizable and does not require a lot of additional space as it sits above the laser bed to load and unload material. With KST, fabricators can have up to 20 shelves and can integrate a second tower to maximize material storage.

Fabricators looking to begin automating their manufacturing process or expand their current automation setup can benefit from the addition of SMART CELL. The robotic sorting system’s flexibility offers first-time buyers and experienced manufacturers simplicity and convenience to automate production.