Discover More at FABTECH Orlando

Join Mazak Optonics in Orlando, FL on October 15 – 17 at FABTECH booth S20085.

Orange County Convention Center

9800 International Drive, Orlando, Florida 32819

| Tuesday, Oct 15 | 9 AM — 5 PM |

| Wednesday, Oct 16 | 9 AM — 5 PM |

| Thursday, Oct 17 | 9 AM — 4 PM |

Attendees of FABTECH Orlando will have the opportunity to connect with Mazak personnel and discuss optimal laser and automation configurations for their unique production requirements.

As leaders in the manufacture of advanced laser-cutting solutions and automation systems, Mazak Optonics provides solutions tailored to your needs.

Visit booth S20085 at FABTECH Orlando to Discover More with Mazak.

TECHNOLOGY ON EXHIBIT

OPTIPLEX 4220 NEO 20kW

The Next Generation of High-Power Cutting Machines with Maximum Control

- Beam shaping technology delivers optimal thick and thin metal cutting, higher cutting speed, superior edge quality, and improved piercing time.

- Large front and side access doors minimize restrictions when loading/unloading material.

- New MAZATROL SmoothLx control features a widescreen and touch panel for ease of operation.

- Rotating CNC display provides flexibility to work at the front or side of the machine.

- Intelligent functions support operators by ensuring optimal laser-cutting performance.

- Camera Assisted Part Nesting quickly and easily processes additional parts on demand, without delay.

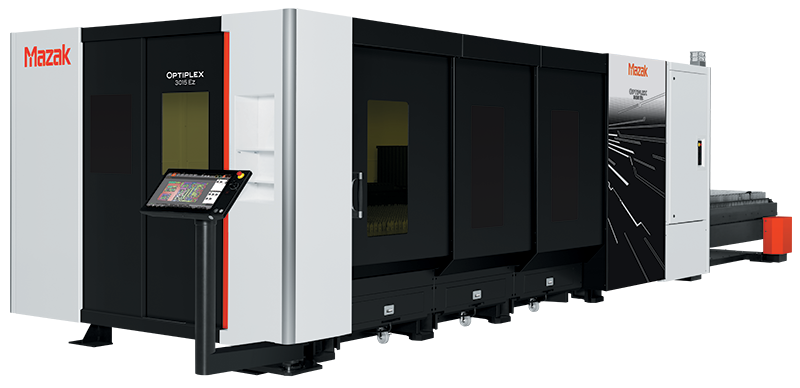

OPTIPLEX 3015 Ez 4kW

Affordable, Entry-Level Laser Processing Solution

- Affordable laser processing solution ideal for entry-level users.

- Available in 4kW and 6kW power options, plus 3015 and 4220 machine size options.

- Ez integrates affordability with the accessible design of Mazak’s flagship flat sheet laser, the OPTIPLEX NEO.

- Large front and side access doors offer easy accessibility.

- Next generation MAZATROL SmoothLx control is easy to learn and operate.

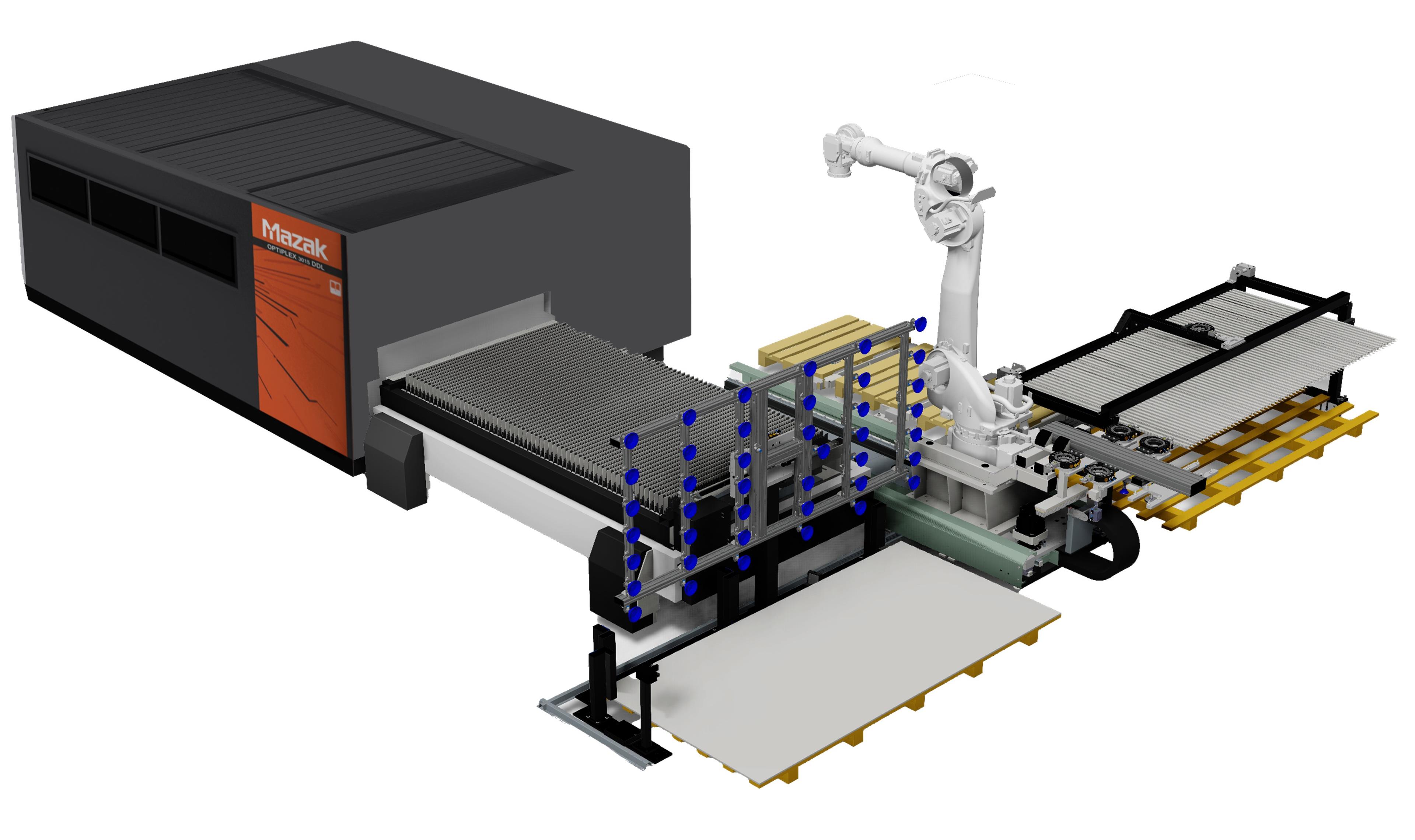

SMART CELL Robotic Sorting

An Economical Investment for High-Performance Automation

- SMART CELL is a 6-axis robot that utilizes interchangeable magnetic and suction cup grippers to sort laser-cut parts, load raw material, and remove remnant material.

- The sorting system is available in multiple size and payload options to sort a wide range of geometry, with the base design featuring a small 20’ x 20’ footprint.

- SMART CELL utilizes Mazak’s SMART SYSTEM software to identify the location of each part based on cutting data from the laser.

- A drag-and-drop feature simplifies programming the robot to unload laser-cut parts in specified positions and arrangements.

- Compatible with Mazak’s flat sheet laser-cutting machines, SMART CELL can be integrated as a standalone solution or with automated storage towers for continuous production.