Increase machine throughput by implementing lights off operations on your laser-cutting machine

by Tim Tapper, Applications Manager at Mazak Optonics Corp.

Wouldn’t it be nice to go home for the night and return in the morning to have two finished sheets of cut parts? Mazak laser-cutting machines can easily be set up to run two additional sheets of material on its own, after hours. Simply load each pallet on the machine with fresh material, tell the machine which job to run, and set up the machine to run the job twice with a pallet change. The machine will run the two sheets of material, then shut the machine down for the night once the job is finished. When you arrive in the morning, both sheets will be cut and ready to unload.

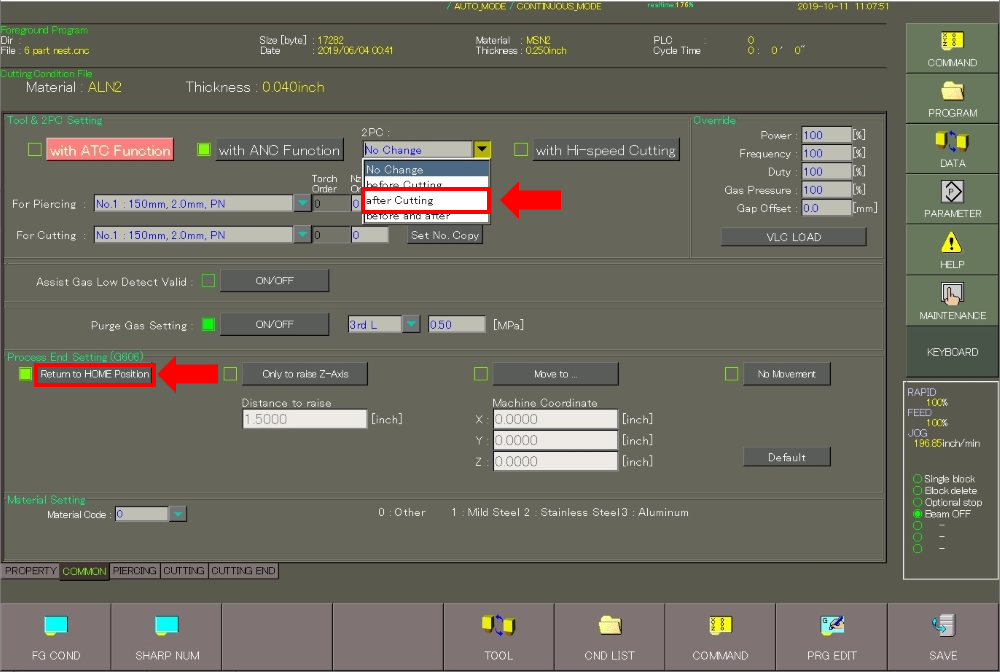

Setting up the Technology Table

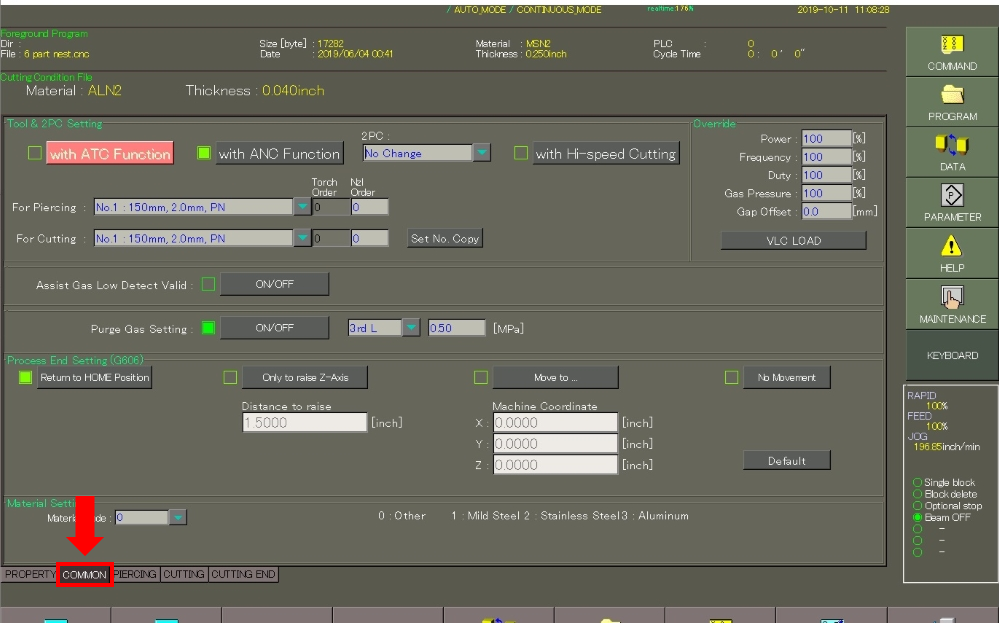

The technology table for each material contains settings which tell the machine what to do at the completion of a nest of parts. This includes instructions of where to send the cutting torch (Home Return the Z-axis, Home Return all axis’, etc…) as well as when or if to perform a pallet change. This information can be found in the COMMON tab of the Tech Table for any material.

Set up the Tech Table to perform a pallet change after the nest has been completed.

1) Open the Tech Table for the material to be processed.

2) Click on the COMMON tab

3) Click on the 2PC menu to expand the options.

4) Set the pallet change option to occur AFTER CUTTING

5) Set the END SETTING (G606) to “Return to HOME Position”

Modifying the Nest CNC Program

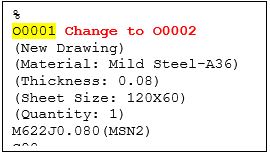

6) Change the nest program number to “O0002”

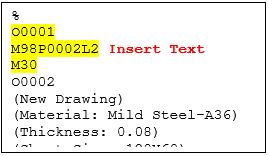

7) Inset the three lines of code shown to the right, after the “%”

Note: This will automatically run the nest program O0002 a second time after completion of the first sheet.

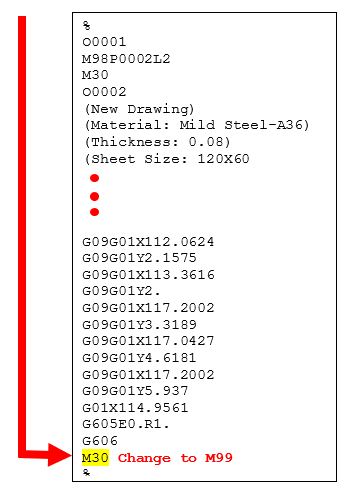

8) At the end of the nest program, change the M30 command to M99.

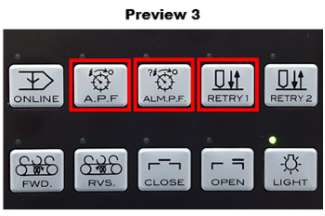

9) Enable AUTO POWER OFF , AUTO ALARM POWER OFF , and 3-TRY RETRY

Note: These functions are controlled by push buttons on the control. Both the Preview 3 and PreviewG configurations are shown here.

Explanation:

- 3-TRY RETRY will try to recover from an auto gap alarm during unattended operation.

- AUTO ALARM POWER OFF will shut the machine down if an alarm occurs that cannot be overcome.

- AUTO POWER OFF will shut the machine down after the completion of the program.

Completing these steps will enable the machine to run two sheets of the same program back to back with a pallet change in between. Once the two sheets have been completed or if an alarm occurs, the machine will turn itself off for the night. Upon arrival in the morning, you should find two sheets of finished parts ready for unloading.

For additional assistance, please contact the Mazak Laser Applications Department at: 1-888-MAZAK US.