| Round pipe Max. workpiece size | Φ10" |

| Square pipe Max. workpiece size | 8" × 8" |

| Max. material length for loading | 255" - 472" * |

| Laser power | 6.0 kW |

Laser Processing Machines

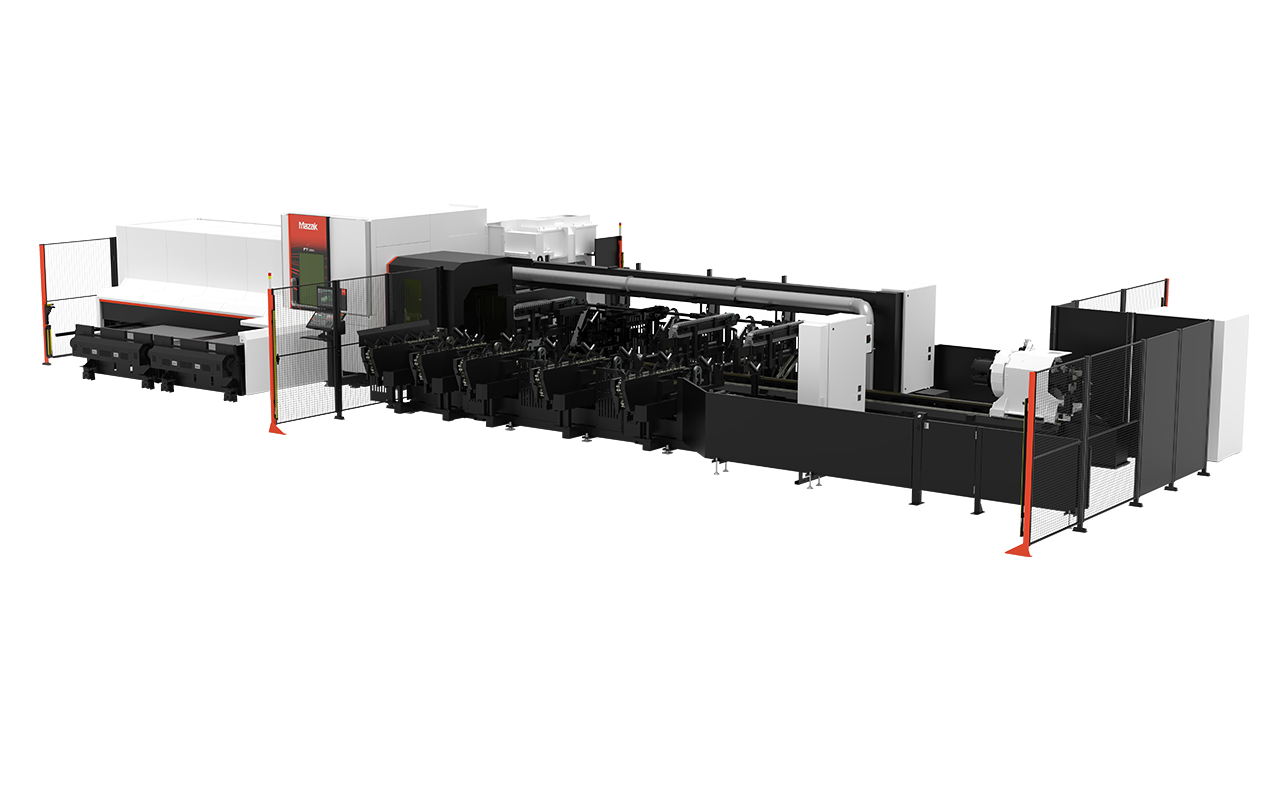

FT-250

- Equipped with Mazak SmoothCUT 6kW laser oscillator

- Achieve high-speed, high-quality processing of long pipes and structural materials

- Reduce production lead times by completing all operations on one machine with the integration of tapping and drilling capabilities

- Extended loading and unloading capacity enables continuous processing

- Equipped with easy-to-operate CNC system, SmoothTUBE

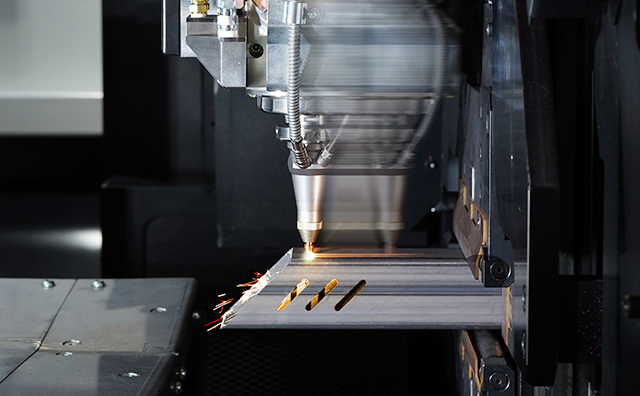

High quality and high production cutting of various pipes

U-axis control for high-speed and high-precision cutting

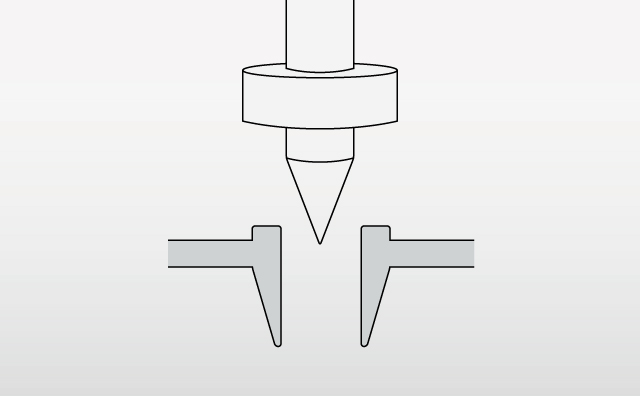

The FT-250 is capable of processing round pipes with a maximum diameter of Φ10" and square pipes with a size of 8" per side. The standard 2.5D laser head also allows bevel cutting. A variety of materials, including mild steel, stainless, copper, brass, and aluminum, can be cut at high speed and precision with U-axis control.

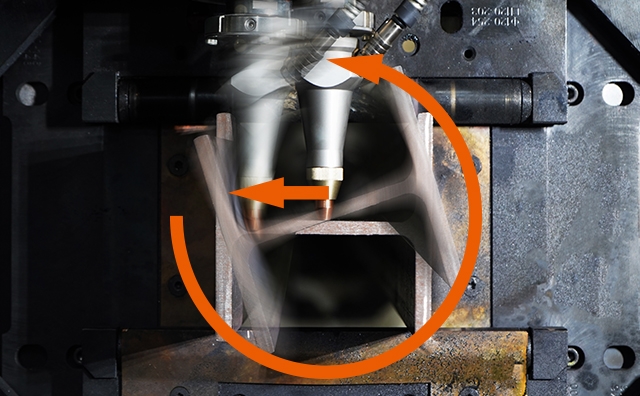

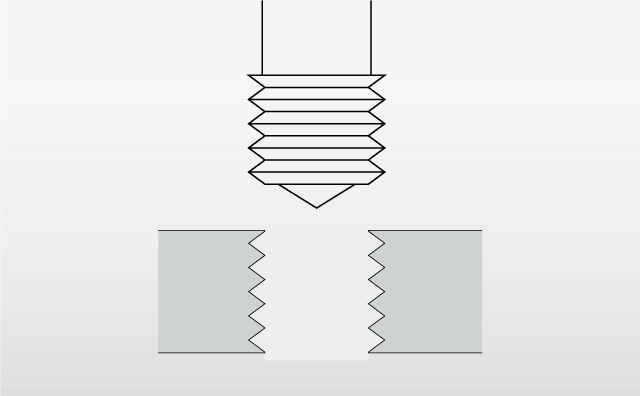

High-quality cutting of structural material using C-axis control

By synchronizing C-axis control and torch linear axis travel, processing various steel beam shapes, including H, I, and L is possible. High-precision processing of complex shapes that combine the joints of shaped steel can also be achieved with high-quality cutting surfaces.

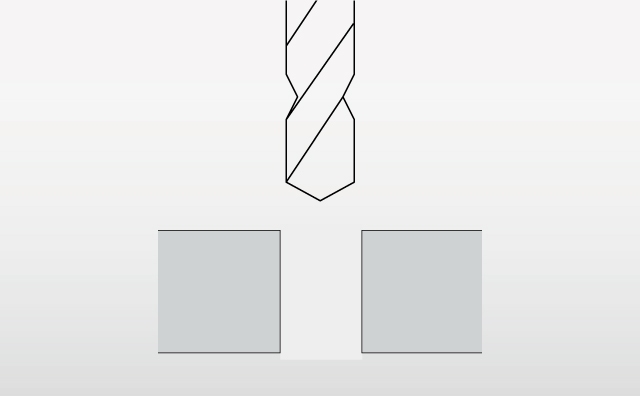

Process integration to improve productivity in mass production

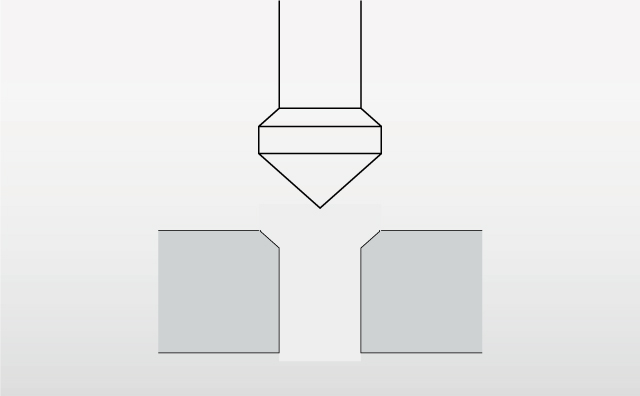

Rotary Tool Unit for drilling and tapping

With 13 positions auto tool changer that eliminate after process and increase productivity. Tools suitable for drilling, tapping, thermal drilling and chamfering can be attached to maximize productivity.

Reduce in-process time of pipe workpieces

By integrating the conventional pipe process, the FT-250 reduces inter-process transfers, waiting time, setup time, etc., and completes all processing on a single machine—shortening production lead time.

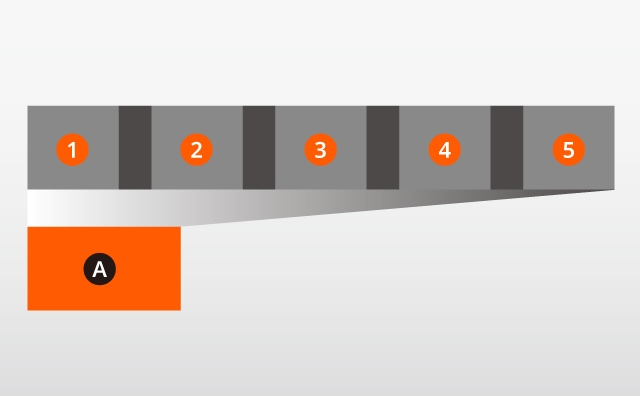

Reduce in-process time of pipe processing

Previous processing

1 : Cutting by saw

2 : Blanking

3 : Bevel cutting with grinder

4 : Drilling

5 : Hole tapping

A : FT-250 completes all processing on a single machine

Automated functions and machine design achieve high productivity with minimum operator intervention

With various automated functions such as calibration settings and nozzle cleaning, the productivity of pipe mass production operation is significantly improved.

Expanded setup and operation area

Chuck setup and maintence areas are conveniently located next the SmoothTUBE control for operator accessibility and efficiency. The unloading conveyor cover located on the front of the machine slides open for easy access to perform setup and maintenance operations.

Selectable loading structure allows for long-term continuous processing

Materials are automatically loaded onto the machine by a high-capacity bundle loader from the rear side. After laser processing, the cut parts are automatically unloaded.

Structural steel and irregular workpiece geometry can be loaded manually.

The V support conveyer loader is a loading system from the front side that allows you to supply different types of structural materials in accordance with your production schedule.

Up to five materials can be automatically supplied, enabling high-mix, low-volume production.

A combination of bundle loaders from the front side and V support conveyer loader from the rear side can be installed to suit your production requirements.

A variety of options that achieve high accuracy and high added value

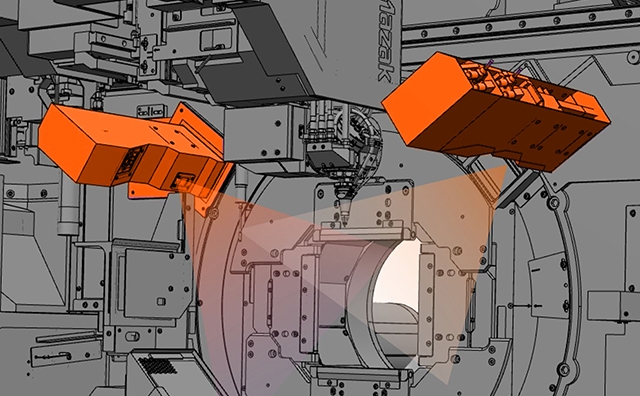

Work Center Location/Inclination Compensation

Measures the OD of pipe material and automatically compensates for material distortion to ensure high precision positioning.

Visual Seam Locator

The weld seam of pipe material can be detected on the machine to determine the required radial position for cutting.

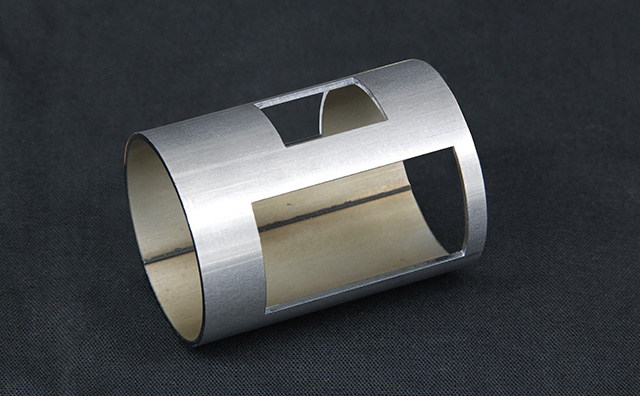

Internal Spatter Guard

The spatter guard protects the internal workpiece surface from spatters and burns, thereby preserving the quality of the workpiece.

Equipped with a CNC system for pipe processing that significantly improves operability

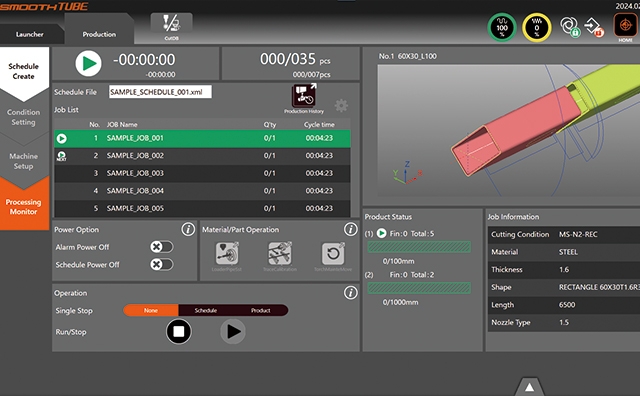

SmoothTUBE, a new CNC system for pipe processing

The SmoothTUBE CNC system features a new graphical user interface specialized for tube processing, which ensures easier operation. The control comes with a dual touch panel and large 21.5" screen. Condition settings of scheduled operations can be updated and reprocessing can be performed on the CNC system easily. The screen configuration assists operators throughout the production process and supports efficient pipe processing.

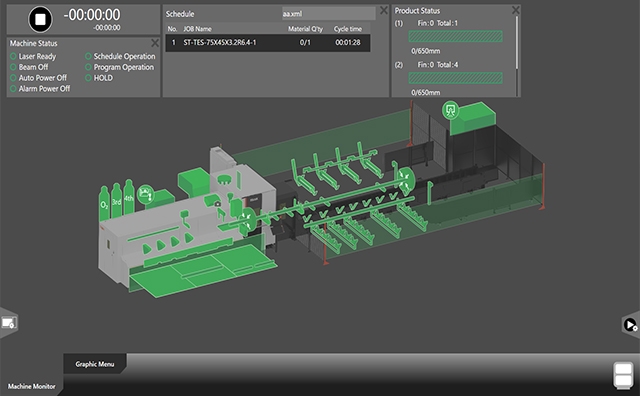

Machine monitor and graphic menu

The Machine Monitor provides an overview of the machine with 3D images and important status updates, including the door's open / closed status. The Graphic Menu supports operators by providing easy access to the torch and machine operation menu. The machine's processing status is also displayed.

Completely supports the processing status

The lower monitor assists operators throughout the production process. Production operations can be completed on the control and monitored efficiently using the newly designed interface. Operators can easily modify condition settings of scheduled jobs and reprocess selected parts directly on the CNC system.

Reference video

FT-250 (V support conveyer loader specifications)

FT-250 (Bundle loader specifications)

| Round pipe Max. workpiece size | Φ6" |

| Square pipe Max. workpiece size | 6" × 6" |

| Max. material length for loading | 255" to 314" * |

| Laser power | 6.0 kW |

*Optional