When programs need to be restarted on a Mazak laser, operators can utilize three different methods to efficiently resume laser-cutting

by Joe Fiorito, Applications Engineer at Mazak Optonics Corp.

During laser-cutting operations, laser users may run into a scenario when a program needs to be restarted. A situation may occur after stopping the machine to check for cut quality or after a collision. Depending on the situation there are multiple ways operators can efficiently resume a program on a Mazak laser. The three most effective methods laser operators can utilize to perform a program restart are through the FEED HOLD, RESTART function, or the GOTO method.

Standard FEED HOLD Method

The simplest and most common way to restart a program is simply through the FEED HOLD and CYCLE START buttons. At any point in the program, an operator can press the FEED HOLD button and the laser will stop in its place no matter where the cutting head is located or what operation it is performing. Now, the operator can open the access door to evaluate inside if needed.

Laser operators can also move the cutting head up and down in the Z-axis but be careful not to travel too high and cause a +Z OVERTRAVEL alarm to signal. When finished, make sure that the machine is in AUTO mode then simply press CYCLE START and the laser machine will pick up where it left off.

RESTART Function Method

There are situations, whether by choice or not, laser operators will have to terminate a program. This is achieved by pressing the RESET button.

There are situations, whether by choice or not, laser operators will have to terminate a program. This is achieved by pressing the RESET button.

If there is a red alarm, operators cannot press CYCLE START to resume cutting where the laser left off. An instance when a red alarm might occur would be if operators get an OVERTRAVEL alarm. If a red alarm does appear, laser operators are also unable to press CLEAR followed by CYCLE START .

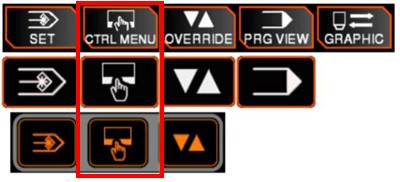

In these cases, the operator will have to perform a program restart. In order to restart the program, first put the machine in AUTO mode and then press the CTRL MENU button on the control. At this point a popup window will appear. On the top row of this popup window, operators will have an option for RESTART .

After pressing RESTART , a popup window will show the operator exactly where the program left off.

“O No” denotes the program number, “N No” denotes the sequence number (number of cuts), “B No” denotes which block, and finally, “L” is which repetition of the program laser operators are on if looping the program.

The operator can now press SET and the NC will figure out where it needs to go. Once the RESTART menu disappears, press CYCLE START then the cutting head will move into position and the CYCLE START button will start flashing. Press CYCLE START one more time and the laser will resume cutting where it left off.

GOTO Method

As an alternative to using the RESTART function, operators can use the GOTO method to restart a program.

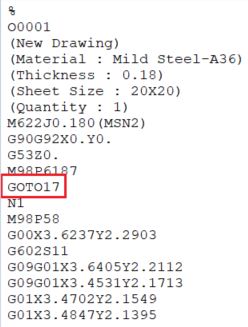

A GOTO statement jumps to exact points in the program, most often where the program stopped.

Once the program has stopped, operators can view where cutting was interrupted by going to the SBR tab on the COMMAND screen. Similar to the RESTART function, operators can see where laser-cutting left off in the program via the sequence number and block number.

However, while using the GOTO function, operators only need to see the sequence number (N No). Operators can type in “GOTO” followed by the sequence number in the program. Once the program reads that line it will adjust to that sequence number. Typically, laser operators can type this line in right above “N1” in the original program.

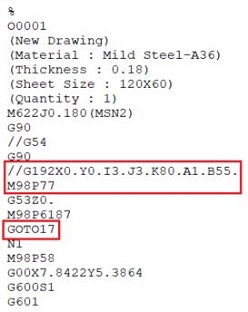

Although, there are instances where operators need to take some additional steps in order to properly restart the program. One example of this is if operators are utilizing Edge Detection.

If a program needs to be restarted that used Edge Detection to set the program’s coordinates, operators do not want to re-run Edge Detection again when restarting. This may cause the program to not come up with the exact same coordinates.

Instead, laser operators can recover the edge detection measurements by inputting “M98P77” into the program. Operators can then restart the program where it left off by block deleting the edge detection with a “//”, typing in “M98P77” underneath it to recover the measurements, and finally, type in the GOTO statements underneath this to enable the cutting head to move to the location laser-cutting needs to resume.

Instead, laser operators can recover the edge detection measurements by inputting “M98P77” into the program. Operators can then restart the program where it left off by block deleting the edge detection with a “//”, typing in “M98P77” underneath it to recover the measurements, and finally, type in the GOTO statements underneath this to enable the cutting head to move to the location laser-cutting needs to resume.

Another example of when additional steps are needed to properly restart a program is when using Nozzle Start programs.

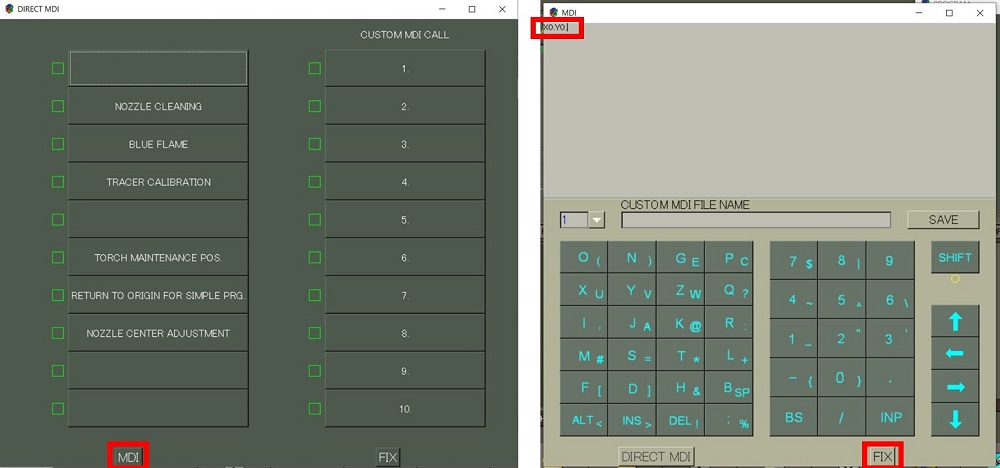

These are programs where the program origin is set by the location of the cutting head when pressing CYCLE START .

In order to properly restart this type of program, laser operators must return to the location where the program began to restart it. To begin this process, press the MDI button on the control. Operators can then close the MDI screen by pressing the MDI button in the popup window so the new code can be entered. Once on the MDI screen, type in “X0.Y0.”, then press FIX , and finally press CYCLE START .

Always make sure that the cutting head is retracted and will not interfere with anything while it is moving back into position.

By using the Standard FEED HOLD method, RESTART function method, or the GOTO method, operators can restart programs on their Mazak laser. These methods will help laser users resume laser-cutting operators quickly and efficiently.

For additional assistance, please contact the Mazak Applications Department at 1-888-MAZAK-US.