OPTIPLEX 4020 CO2

A flexible job shop laser-cutting system that does not compromise performance

PROCESS: 2D, FLYING OPTICS, 2 PALLET CHANGER

MACHINE DESCRIPTION

The OPTIPLEX 4020 CO2 offers unique flexible performance features that specifically meet the needs of high variation job shops.

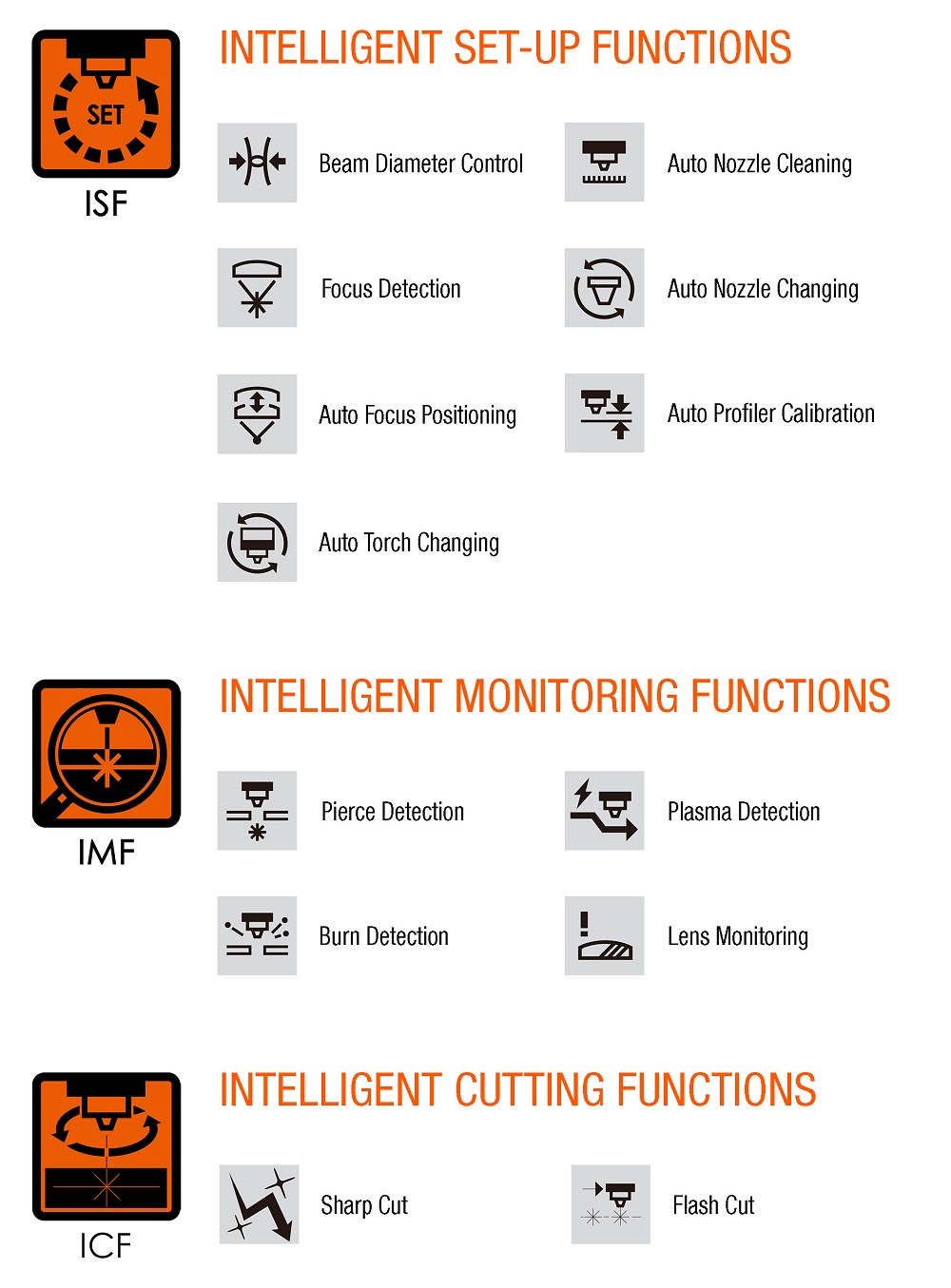

Designed to integrate Intelligent automation features with superior cutting speeds, the OPTIPLEX uses Mazak’s AO|5 automated setup functions. This AO|5 system overcomes the typical challenges of using varied workpiece materials by improving productivity without compromising cutting conditions. These optimal cutting conditions can even be retained during extended unattended operation.

The OPTIPLEX also features the new Preview 3 control with a 15” touch screen and straightforward user interface to simplify machine operation. The graphical interface clearly visualizes the cutting path and automatically determines process conditions including the required lens, nozzle, feedrate and laser output for different materials and thicknesses.

The OPTIPLEX 4020 CO2 can process sheets up to 6 feet by 12 feet. OPTIPLEX CO2 series machines are available in 2.5kW, 4.0kW and 6kW configurations.

PERFORMANCE ADVANTAGES

- A 2 pallet changer design with a helical rack and pinion positioning system that features high throughput and rugged construction delivers a combination of performance and value.

- New PreView 3 control with touch screen and integrated tech tables simplifies operation.

- AO|5 with zero setup assures optimized operation with less operator dependency.

- New Type 10 resonator with ECO Mode lowers operating costs.

INTELLIGENT TECHNOLOGY FUNCTIONS