Mazak iSMART Factory™

Take raw data, read and analyze it, then turn it into actionable information

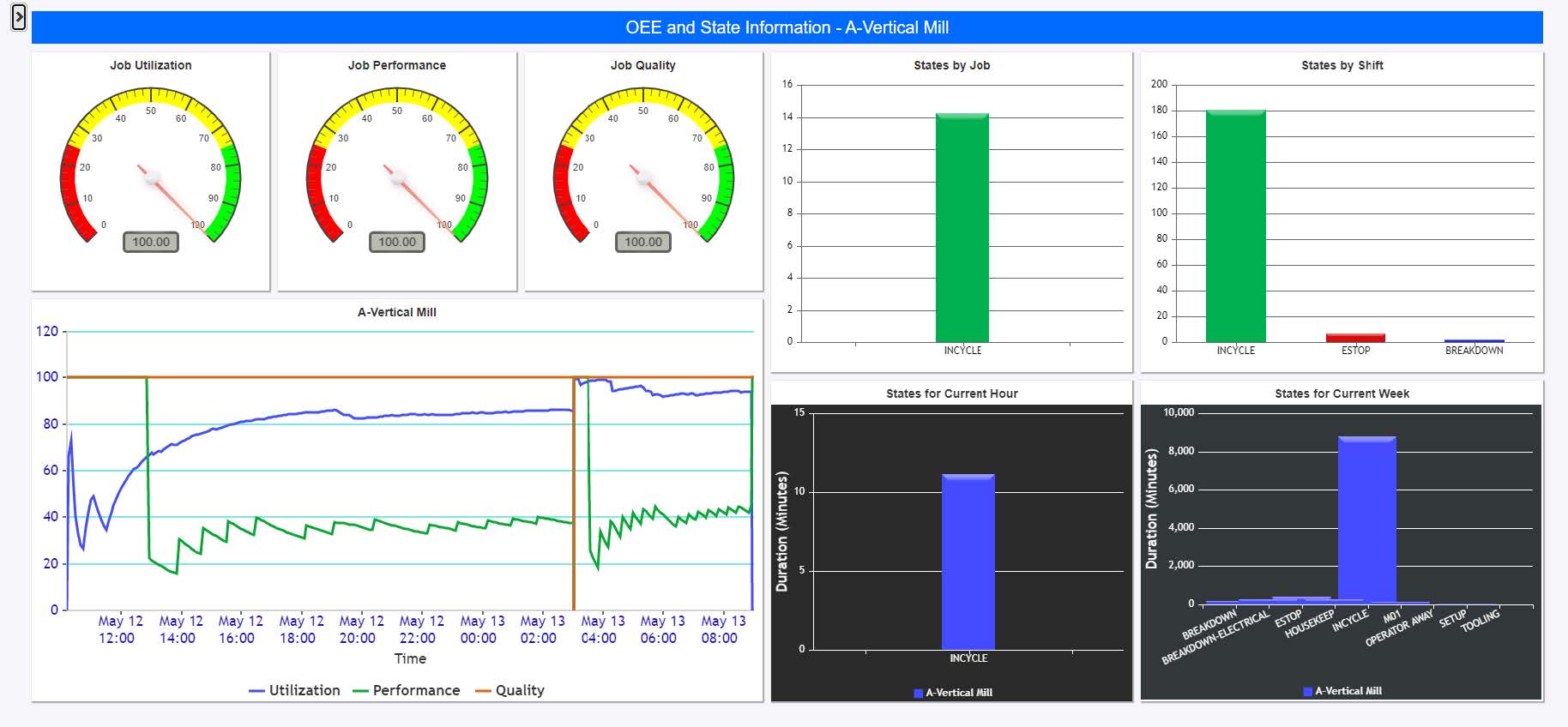

An element of the Mazak iSMART Factory™ concept is the ability to utilize software that enables you to visualize the performance of cells, departments and the overall plant as compared to historical or target performance. These insights are the real-time tools that can enable fabricators to manage the process rather than reacting to historical reporting.

- See the productivity and increased profitability as it happens in real-time

- Productivity problems can be identified fast - accelerating resolution

- Plant-wide productivity increases in the range of 10% to 50%

- Dashboard metrics can be available for everyone on the shop floor to see

Mazak iSMART Factory™ offers an industrial internet platform solution for manufacturing including hardware, software machine monitoring solutions that connects directly to manufacturing equipment. It is designed to monitor every machine in your shop, CNC machines, non-CNC machines, fabrication centers and manual processes, all tied together in a production process manufacturing execution system.

Machine monitoring delivers instantaneous, automatic and timed proactive email and text alerts to minimize downtime. Detailed analyses of downtime root causes points to areas requiring more operator training. Identification and removal of unnecessary optional stops helps recover lost production time.

MTConnect® is an open-source, royalty-free manufacturing protocol that easily connects devices and systems from different suppliers to capture and share information in a common format, such as XML. Mazak has incorporated this protocol within our machines to help standardize and simplify communication. It is a cornerstone in the implementation of Mazak iSMART Factory™ capabilities.

Above is an example of one of the many screen page configurations that can be generated by Mazak iSMART Factory™ software. It displays a dashboard of overall metrics or Key Performance Indicators as compared to targets including Overall Equipment Effectiveness (OEE). OEE is a statistical measurement (OEE = Availability x Quality x Performance) used to determine how efficient a machine is running.

Below are further details about the Mazak SmartBox.