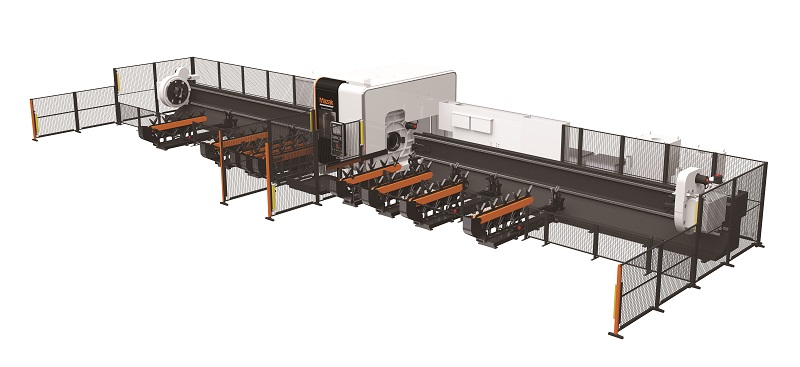

3D FABRI GEAR 400 III

Rugged 3D precision for tube and structural applications

PROCESS: 2D/3D, HYBRID DESIGN

MACHINE DESCRIPTION

The 3D FABRI GEAR 400 III machine excels for an expanded range of laser-cut tube, pipe and structural applications. Available with a 2.5kW or 4.0kW resonator, the 3D FABRI GEAR 400 III cuts a wide variety of tubes and pipes including round, square, rectangular and triangular. It can also process I and H beams, C-channel, angle iron and additional user-defined shapes from mild or stainless steel. This extensive range of capabilities makes the machine ideal for many industries and applications.

Featuring a powerful, high-precision 6-axis laser, the 3D FABRI GEAR 400 III can handle larger, longer, thicker and heavier material than similar machines due to its rigid workpiece handling system incorporating a four chuck design. It also has improved processing speeds, tighter tolerances and can be used for drilling and tapping.

PERFORMANCE ADVANTAGES

- Powerful, 6-Axis laser with automated load/unload functions.

- The 3D FABRI GEAR 400 III cuts a large range of mill-length tube and pipe, whether round, square, rectangular, or triangular. In addition, it can completely process I and H-beams, C-channel, angle iron, and additional user-defined shapes.

- 6-axis laser cutting means you can cut at any desired angle for weld prep, plus achieve the highest accuracy for easy fit-up of assemblies - all in a single program cycle. Program-controlled loading, workholding, and unloading make it an efficient fabrication cell requiring minimal labor input for small to large volume part production.