LASER FLEX

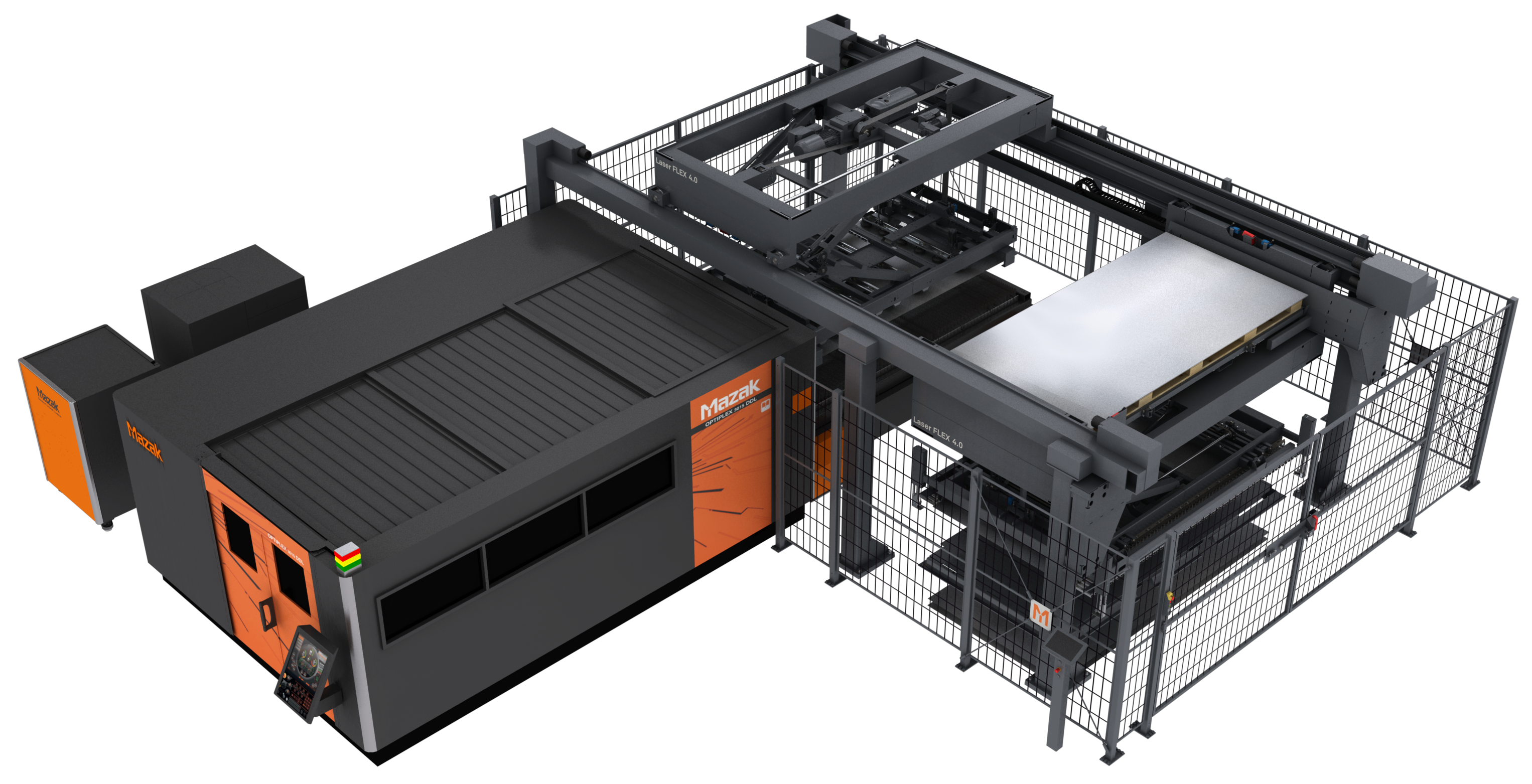

High throughput automation system for production environments

PROCESS: 2D AUTOMATION

SYSTEM DESCRIPTION:

LASER FLEX automation systems are designed for high volume production environments. They have a modular design and are available in a wide range of configurations and features that can be customized to facilitate throughput. LASER FLEX systems utilize independent load/unload functions to accelerate sheet-to-sheet cutting productivity. Sheets are loaded utilizing a suction cup based system and unloaded by a clamshell fork system. The clamshell forks can optionally be ordered with a SOFT TOUCH belt system to reduce the possibility of scratching finished workpieces. Towers can be added for load/unload capacity while cart systems and conveyors allow workpiece separation as production continues.

LASER FLEX systems are available in a variety of 3015, 4020 and reverse flow configurations. They can be integrated into an automated storage/retrieval system for even greater capacity.

Mazak’s LASER FLEX automation can also be designed to incorporate systems to separate parts and automatically load them onto pallets in production environments.

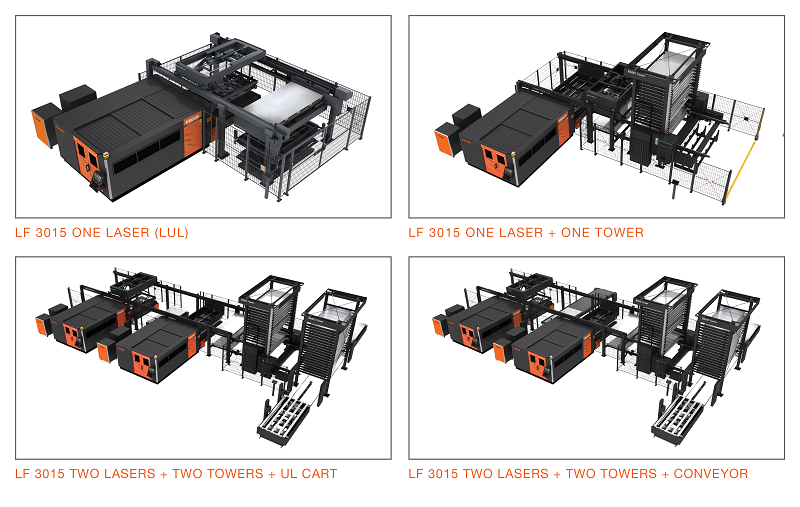

CONFIGURATION EXAMPLES: